Timm Ranch Yarn

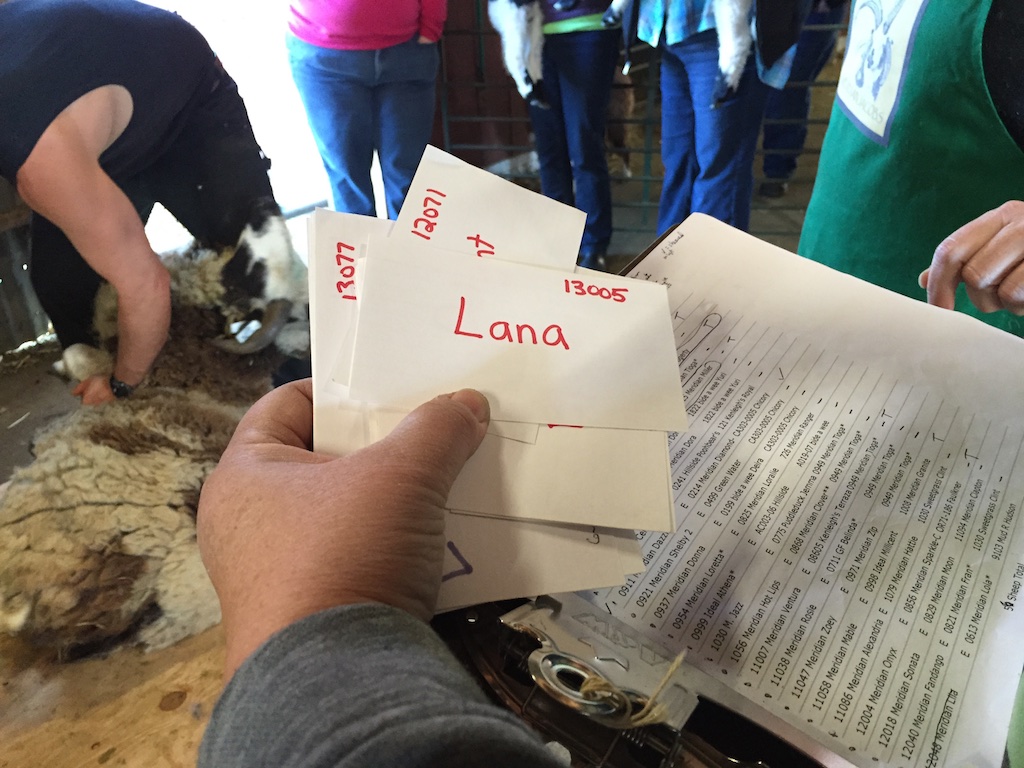

/I bought 200 pounds of wool at the Timm Ranch shearing last April. There are photos of the sheep and the ranch in this blog post and more photos and shearing action in this video.

Due to health issues at the mill where I sent the wool it took longer than usual to get it back, but it finally came in late December.  I hadn't had a chance to do anything with it until recently. The first step was to gather some information.

I hadn't had a chance to do anything with it until recently. The first step was to gather some information. The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances.

The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances. Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average--1500 ypp.

Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average--1500 ypp. Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn't quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really "finished".

Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn't quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really "finished". Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)...

Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)... and it is 10 wpi. Based on those measurements I wove some samples.

and it is 10 wpi. Based on those measurements I wove some samples.

Here is a brief weaving lesson (and maybe more than you really want to know). If a yarn measures 10 wpi an approximate plain weave sett (that's the number of warp threads) for a balanced weave structure may be 5 or 6 epi (ends/inch) because you must allow for the weft yarns to go in between each of the warp yarns. In weaving a pattern you would use a denser sett (maybe 8). I wove samples at 8 and 10 epi. These samples look pretty open on the loom...

These samples look pretty open on the loom... ...and I had to be careful to not beat the weft yarn down too much.

...and I had to be careful to not beat the weft yarn down too much. This is how the samples look off the loom. The 8 epi samples are in the top row.

This is how the samples look off the loom. The 8 epi samples are in the top row. And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric.

And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric. Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren't just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit.

Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren't just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit. This was knit over a few weeks with a new direction given out each week.

This was knit over a few weeks with a new direction given out each week. It is gorgeous in person and has a wonderful hand. I can't wait to get some of this yarn on the loom and get to work with it.

It is gorgeous in person and has a wonderful hand. I can't wait to get some of this yarn on the loom and get to work with it.

The yarn is listed here on my website.

This is the yearling ram, Rotor.

This is the yearling ram, Rotor. A good comparison of a lilac Jacob (Nash) and black & white (Rotor).

A good comparison of a lilac Jacob (Nash) and black & white (Rotor). This is Rotor's fleece.

This is Rotor's fleece. They aren't all spotted. This is one of the BFL-Jacob cross ewes.

They aren't all spotted. This is one of the BFL-Jacob cross ewes. Lots of people help to make Shearing Day fun and easy for me. Kathleen weighed fleeces.

Lots of people help to make Shearing Day fun and easy for me. Kathleen weighed fleeces. Stephany and Gynna wrangled sheep all morning.

Stephany and Gynna wrangled sheep all morning. Alison and many others helped at the skirting table.

Alison and many others helped at the skirting table. People are welcome to skirt their fleeces before buying or ask for advice about fleeces.

People are welcome to skirt their fleeces before buying or ask for advice about fleeces.

It was a great day to stand in the sun with your hands in freshly shorn wool.

It was a great day to stand in the sun with your hands in freshly shorn wool. One more ewe to be shorn and then it was Faulkner's turn.

One more ewe to be shorn and then it was Faulkner's turn. His buddy, Jerry looked on. Faulkner weighed in at 235 lbs (down about 30 pounds from what he sometimes weighs in the summer).

His buddy, Jerry looked on. Faulkner weighed in at 235 lbs (down about 30 pounds from what he sometimes weighs in the summer). Fresh Jacob fleece.

Fresh Jacob fleece. Faulkner's fleece.

Faulkner's fleece. While the shearing and wool sorting was going on, friends were helping buyers in the shop.

While the shearing and wool sorting was going on, friends were helping buyers in the shop. Later we got everyone (almost) to the barn for a group photo. That's a lot of enthusiastic friends!

Later we got everyone (almost) to the barn for a group photo. That's a lot of enthusiastic friends!