Awards for Weaving

/Awards won for weaving and sheep at this year’s festivals.

Read MoreJuly, 2023: I have switched to writing most of my blog posts on my original WordPress blog so access all the current news there and sign up on that site for email updates.

Awards won for weaving and sheep at this year’s festivals.

Read MoreRandom farm photos of what I’ve been doing—irrigation, weaving, teaching classes, skirting fleeces, monitoring lambs to sell.

Read MoreRandom photos of the farm during the last week—lambs, weaving projects, classes, and even a horse.

Read MoreI wrote this blog post just after Shades of Black and White opened at the Artery September 30. Monday, October 24 is the last day. Some pieces have sold. Of those that have not sold, some will be incorporated into my space in the main part of the store and the others will go on my website or the Artery’s webstore. I thought I’d share some of my favorites.

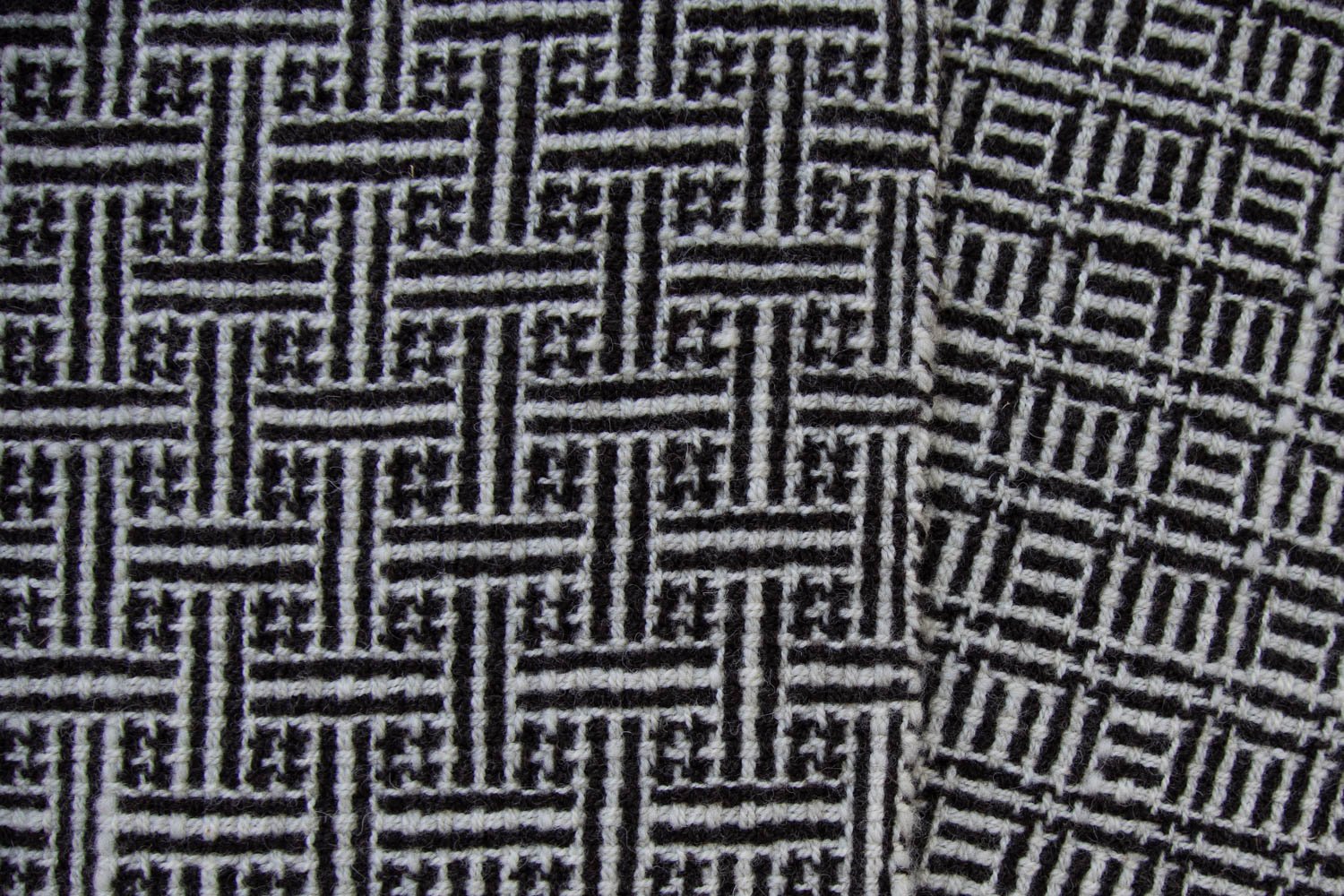

This shawl is woven with my locally sourced Timm Ranch yarn except for the three black lines that are Jacob wool. It is a simple pattern, but time consuming. The design is woven on the loom as the weaving progresses.

This is another one. Only a small portion is visible at any one time so it’s a bit of a challenge to keep track of where those right angle designs are happening as you go. .

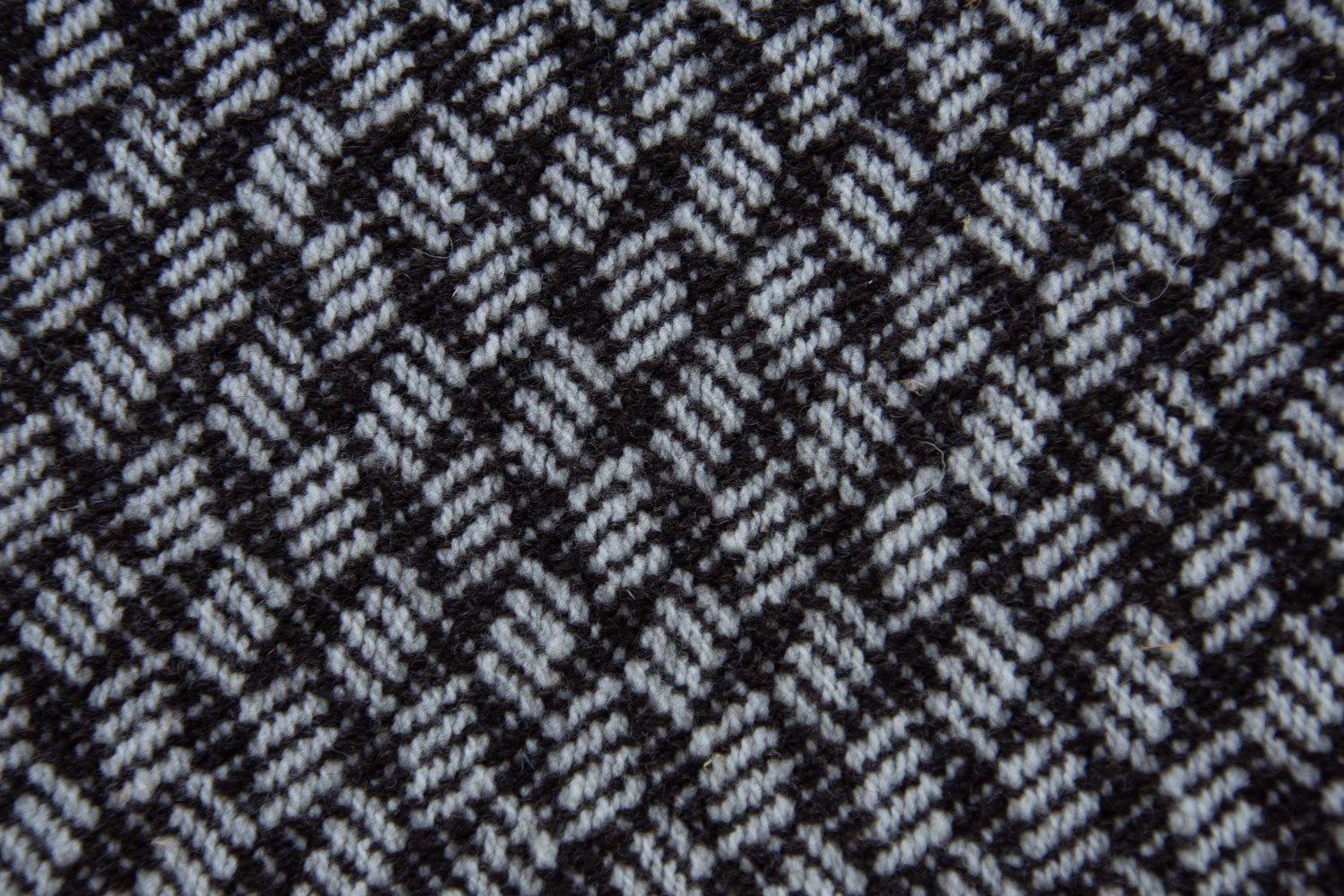

This was a favorite 8-shaft pattern in 100% Jacob yarn. It is relatively easy to thread and to weave. The two sides look very different.

This is a draft that will produce pinwheels or many other interesting shapes.

This is another favorite. I’ve always liked this tumbling blocks pattern. Jacob yarn on a Timm Ranch wool warp.

What about simple stripes? This is warped with alternating columns of 4 threads black and 4 threads white. The weave structure allows the yarns to open up when this is off the loom. Those stripes look like columns of beads. 100% Jacob yarn.

This was a new pattern for me and I like the movement in it. Jacob weft on Timm Ranch warp.

This is a bag woven of hemp. I didn’t find room for it in the show so it’s at home now. It will probably go on my sebsite.

Another color and weave pattern. Both these scarves were on the same warp. They use 100% Jacob yarn.

This is the last piece I wove—two nights before the show opened. I was talking to someone when the idea of Clasped Warp came up. I had planned to weave a clasped warp shawl, but forgot until now. I had enough time to put on a scarf warp. The photo below is after finishing.

The joined warp threads are placed in a diagonal line to almost the far end of the warp. This is 100% Jacob yarn.

For the last couple of months I’ve been weaving in black and white. For years I have thought about presenting a show at The Artery featuring black and white weaving. The Artery in Davis is an artists’ coop with 60+ members. It is set up like a regular store where we all have a small area for our own pieces. There is pottery, woodworking, art quilts, jewelry, paintings, gourd art, other fiber art, and more. There is one room known as the gallery where one or more artists can fill the room for their own show. With 60 members we obviously have to take turns. My turn came this October. When I found out a year ago that I’d have the show I wondered if I’d have enough to fill the room (although in the past I never had that problem), so I asked Jock Hamilton, one of the photographers at the Artery, if he’d like to share the space with black and white photography. It turns out that we could have both done our own shows with the amount of pieces we brought.

I wanted to give Jock most of the wall space since he would exhibit photos. I needed to figure out a way to display my pieces where they could be seen without just making a pile of folded textiles. I gave Dan the task of creating A-frames for me. I also brought home several of the wooden mannequins that needed re-painting.

The show was to be in place by Friday and I brought things in on Wednesday. Jock and I had a plan of sorts—that was to bring all of our things and see how they fit together. Hmmm…maybe not much of a plan. I needed to get things out of boxes and start spreading them out. I had to be home by 2 that day but returned later in the day when Jock could bring his photographs. We spent most of Thursday arranging things and I went back Friday morning to finish with signs and tags. Then I had to go to Lambtown in Dixon to set up my vendor booth for the weekend.

The following photos are how the gallery looks now. This show will be in place through October 24 and I hope many of my followers will be able to see it. Any items that are purchased may be picked up after the 24th or arrangements may be made for shipping. If you can’t get to the Artery but want to see most of the pieces here is a link with Jock’s photos and my woven pieces.

It seems that I turn everything into a learning experience. I added these baskets of wool and the sign to the table at the front. I wanted to somehow make people aware that I didn’t just go to the yarn store for all this yarn. Almost all of it is the wool from my Jacob sheep or the locally grown Timm Ranch wool that I have processed. I have handled every fleece before it ends up in the batch that is spun. Most of this is mill-spun but there are a few pieces woven of handspun yarn as well. There are also a few scarves woven of rayon chenille.

I also wanted to explain the name, Shades of Black and White, so I made this sign.

This is the first view of the show when you walk into this room.

Jock’s photographs are along most of the walls, but I hung a few of my pieces.

These are all v-shawls.

I should say something more about the photographs. They are fabulous views of mostly local landscapes. My photos of the photos can’t really show them, especially with the glare. Make sure you go to the link above to see them properly.

This rack holds shawls and scarves. Two of these are chenille but the rest are all Jacob wool.

Blankets that are woven with Jacob wool weft and Timm Ranch wool warp.

Another view of blankets and shawls. Those pieces on the mannequins are mobius shawls.

You have to touch the textiles to feel how soft they are. I was certainly pleased with the Jacob wool the last couple of years.

I hope that a lot of people will see this show. It was quite an undertaking.

This post is just what it says. I’ve taken so many photos with the intent to share them and tell a story, but then I don’t.

Sheep waiting in the shade. They come and go and are in the pasture even when it’s over 110 degrees like it was two weeks ago.

That’s a screenshot from my phone one of those hot days. I forget now how many it was in a row of over 100, but considering that some were over 110 it sure felt like a lot. Thank goodness that is over for now.

Two ram lambs that show a big difference in the spread of their horns. I’d like to hang onto both of these rams for different reasons. They both have good fleeces. The one with the wider horn spread is unrelated to most of the flock. The other is a shade of lilac (that brown/gray color of some Jacob sheep). If I can keep them for several months to a year it will be interesting to see how their horns look at that time.

Before I box and ship pelts for tanning I take photos so I have a record of what I sent and where I sent them. I have shipped 20 sheepskins in the last week or so. It will take from 3 to 5 months to get them back depending on where they were sent.

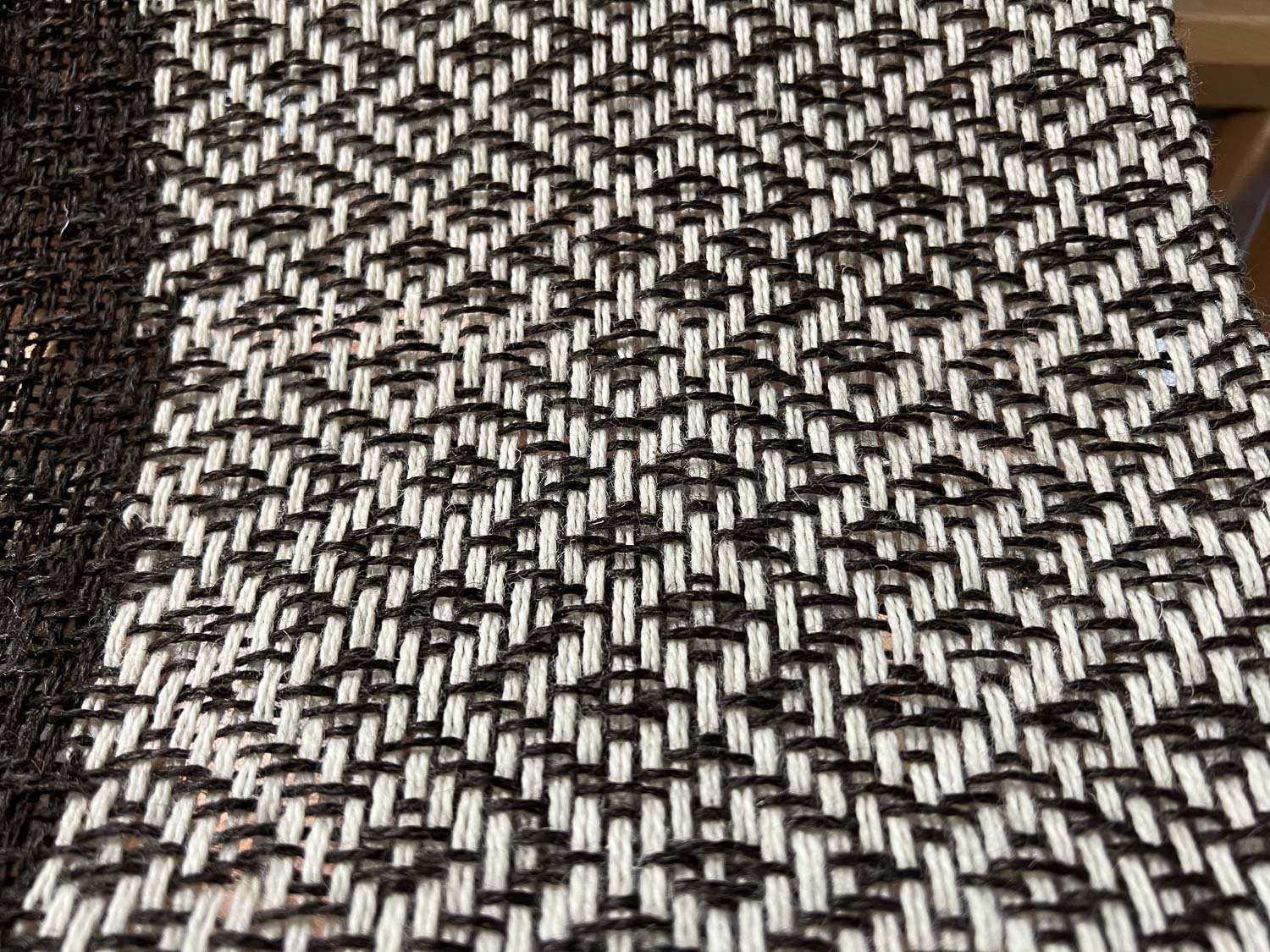

I’m spending a lot of time on preparing for the Shades of Black and White show that will be at the Artery for 3 weeks in October. In fact I will be setting this up the day before I set up my vendor booth at Lambtown. A lot going on. These are some of the latest blankets to come off the loom. These blankets use Timm Ranch wool warp and Jacob weft. They are very soft and I’m thrilled with both of these yarns this year.

This is Jacob wool warp and weft in progress on the loom.

This is how that fabric looks after wet finishing. I turned this one into a mobius shawl. The twist in it allows you to see both sides of the fabric at once. There is no right and wrong side.

This is where I left off tonight on a black and white Jacob blanket.

I was loading the truck today for tomorrow’s event and I heard a suspicious crackling sound across the “bamboo” fenceline that separates us from the neighbor on the north. (It’s not really bamboo, but an undesirable species, Arundo, although it makes a great windbreak for us.). I walked around the fenceline and into the next-door driveway. There was someone standing near the bushes on the right monitoring the fire. Still, with conditions so dry it’s a bit nerve wracking to see.

The neighbor on the west called me this afternoon to say that she saw smoke and called the fire department. They told her it was a permitted fire. I’m surprised that anyone was able to get a permit at this point. Let’s get some rain first.

When you see the title, Random Farm Photos, you know that I’ve either been too busy or too distracted to spend time working with my photos and putting together a cohesive story. Busy and distracted go hand-in-hand. Sometimes the hardest thing to get past is the decision making. Where to start?

I finally finished weaving off a 27 yard warp that was on my big loom. The decisions here are all about where to post the finished pieces. These blankets are woven with locally grown Timm Ranch wool yarn in the warp and weft yarn of various sources. The green is my new favorite non-local yarn that I sell here. The others are leftover yarns that I used to carry—U.S. grown yarn dyed by Sincere Sheep. I can sell these on my website or at the Artery in Davis, or on the Artery’s new shopping website. I finally got the photos taken, but haven’t had time to post them anywhere yet. That’s on the list for next week.

These are more of the blankets from that warp. These can be posted on my website or on the N.CA Fibershed Marketplace website. I listed a few of them on that site tonight, but didn’t finish, and I haven’t decided where to post them all.

This blanket was on that same warp. This is one of my newest ideas and you’ll be seeing more about this as I go further. The colors in this blanket indicate the temperatures throughout the year in my area, progressing from wintertime 40’s and 50’s (gray and blue) all the way to over 100 (red) and back to winter. I’m planning to offer this as a kit for weavers and as a blanket that can be customized for a specific year and/or location.

Next up on the loom is this 50 yard warp. It’s on the warp beam but not threaded yet and there is a deadline. So what am I doing sitting at the computer right now?

More distractions and more decisions. I sorted lambs last week and tried to start making decisions about which I really wanted to keep. That’s hard when you like them all. These are some that may be on my list.

This ewe lamb doesn’t have a great spotting pattern, but she is one of the very few lilac lambs born this year and I want to keep a lilac. (Lilac refers to the color on her face that is not black—her fleece will also be a gray/brown color other than the black and white sheep.)

One of the things that I really needed to do was to finish skirting and sorting fleeces. Lots of decisions there. Which fleeces to put on the website? How much VM (vegetable matter) is too much to go in the barrels for processing at the mill? Do I save back a couple of fleeces for potential Sheep to Shawl contests later in the year?

I’m glad to say that I finally finished with the 2021 fleeces and they are ready for the mill. I had already sold most of the wool I had on the website, but now I have added a few more 1-pound lots of the best parts of the fleeces—those with minimal VM.

I had to make a decision about what to do with this ewe named Alice. It’s a long enough story for a blog post all by itself. I’ll just say that over a week ago I found her by herself and obviously in not very good shape. I am convinced that she had some kind of neurological problem and was blind in one eye. That was in addition to her poor body condition. I brought her to the barn. First decision—vet or necropsy lab or watch until Monday? (It was Sunday and everything would be twice as expensive for maybe not much return.) The rest of the week I kept pondering the pros and cons of all those options. She seemed to be better, but not normal and I wanted help with the decision about the final outcome. So I took her to the VMTH on Friday. There really wasn’t a diagnosis but ideas of what could have been wrong. I came home with medications to be administered twice/day for five days. During this time I had removed the lambs because they are plenty big enough to wean and Alice had no interest in them. After the five days of treatment when I put Alice back with the flock her lambs found her and decided that they were NOT weaned. She welcomed them back and right now you can’t tell that she very had a problem except that she is still skinny—but her behavior seems back to normal.

I’ll end this post with a goat picture. These are two of the triplets and they have decided that this feeder is their personal sleeping platform.

This is Belle, a 2 year old lilac ewe. Lilac is this color in Jacob sheep that is kind of a gray-brown instead of black. She is pregnant and due to lamb in a about a week. What is special about Belle—at least any more special than any of the other sheep? She is owned by my granddaughter, Kirby.

Way back in 2019 when we all had normal lives, Kirby’s family came from their home in Texas to spend a couple of weeks in the summer. I had selected a lamb to register in Kirby’s name and I got her gentled down before the family got here. This is the story and photos of Kirby coming to the State Fair and showing her lamb.

This is one of my all time favorite photos. Kirby was thrilled to win a pink ribbon! What color is better than pink when you are a 5-year old girl?

I wish I had photos of Belle being shorn and of her fleece. Instead the story will fast forward to fall, 2020. I spun Belle’s fleece, shorn in February 2020, during our weekly Farm Club spinners meeting on Zoom.

I had decided that I would weave a blanket for Kirby to send her for Christmas.

I gave up the idea of spinning all the yarn for the blanket because I just didn’t have time and I knew that the Timm Ranch yarn I use for many of my other blankets would be just fine for warp. I wanted a generously sized blanket so I warped for a double width piece.

I wove random stripes of the handspun brown and the mixed white yarn.

I shipped this blanket on December 14 with plenty of time to arrive before Christmas. However, I made an error in one digit of the zip code. There is a long story to follow, most of which I have forgotten now, and that’s a good thing. I got a message from FedEx that the package could not be delivered. I think it had ended up in a small town in Texas not that far from where it was supposed to go. I corrected the zip code and supposedly all was well. But it wasn’t. I spent countless hours on-line and on the phone trying to track down this blanket and get it sent to the right address. Katie offered to pick it up at a FedEx office, but I was told that wasn’t going to work. The blanket was eventually shipped to Tenessee (FedEx center of some kind) and then to Mississippi to what is called “Overgoods”. It turns out that is a depository for packages they don’t know how to handle or that are lost. The tracking information kept saying that it had been delivered and signed for. I had to insist that it was not delivered to the intended recipient. I eventually worked my way up the management ladder and found that the only way to get the package out of Overgoods was for me to set up an account and request the package.

I did that and eventually got the package back here in California on January 12. This is how it looked. I shipped it back to Texas via good old U.S. Mail.

Kirby has been using the blanket on her bed, but I asked Katie to get some photos so they went outside.

We have all heard about the extreme weather in Texas last week so I think the wool blanket came in handy. Kirby is looking forward to Belle’s lambs and has asked me if she can name them.

This is a post with no theme other than the snippets (is that a word?) of all the stuff I’ve been doing.

I got my second batch of the 2020 Jacob fiber back as yarn. The first batch of 2020 wool was spun at Valley Oak Mill and is listed here. This batch is from Mendocino Wool Mill and is listed here. It always take me a little while to figure out how to best present it for sale. I had some put on cones and some in skeins. The yarn on the cones appears to be so much finer than the skeined yarn but it’s the same yarn—it is just under more tension when wound on a cone. I wondered how much the skeined yarn would bloom when washed. That information is important to know when you are planning a project. Whether you are going to knit, crochet, or weave with the yarn you need to know what will happen to the piece when it is washed.

I washed a white and a black skein to see what would happen. In this case washing just means soaking in hot water and then hanging to dry. This is four skeins of yarn. Can you tell the difference in the yarns on the outside and in the middle? The middle ones have not had any treatment. The outside skeins have been washed and the character is very different.

One way to measure the change is by looking at wraps per inch (wpi) before and after. In this case the black yarn measured 14 wpi before washing and 10 wpi after. If you don’t allow for this post-washing change then you may be surprised at how the finished piece looks and behaves. I will wash all the skeins before labeling them.

Another test before selling the yarn is how it actually works in use. I wove scarves of each batch of yarn to compare them and to determine the best sett (spacing of the yarns on the loom). I tried each at 8 epi (ends per inch) and 10 epi.

I photographed these so that the light was behind and you can kind of see the spaces between the yarns. Those spaces are nothing like when the scarves were still on the loom with the yarn under tension. When you cut the piece off the loom the yarns relax and they further relax and “bloom” when fulled in hot water. This photo shows 2 scarves from each batch of yarn at 2 setts each. All four turned out great and even though the yarns appear different, it’s hard to tell the difference in these finished pieces. I look forward to using these yarns in some much larger projects next.

By the way I put these scarves on three different websites—here on my own, on the Fibershed Marketplace and the Artery webstore, all the while carefully keeping track of which one is where so I don’t take a chance on double-selling them.

Another project I’m working on is recording some videos for the Learn to Weave class using the rigid heddle loom. I am going to teach this on Zoom next week and I want videos for students to refer to when we’re not on Zoom. I warped the rigid heddle loom with all four of those new Jacob colors and wove a short scarf while recording most of it. I haven’t wet finished the scarf yet, or edited the videos. (Thanks for reminding me.)

I also finished another v-shawl. This is another thing on my list of things to do. I want to put together a kit for this shawl and give options for the stripe design. I’ve woven several. I just need to get the instructions put together and figure out the best way to present it. I just added this shawl to the Artery web store along with one of the pinwheel scarves.

I still have a barn full of fleeces. I spent some time yesterday working on those. I only have two full fleeces listed on the website so far, but I have listed several 1-pound batches for people who would like to start with raw wool but not start out with a whole fleece. I am skirting, sorting, and photographing. Raw wool is listed here.

Here is another example. In the meantime I want to get my hands in this and start working with it myself. There are some really gorgeous fleeces here.

I said this was a bunch of random photos. So far it is all about wool and weaving and the things I need to do. So let’s get random. Dan saw me weaving and my weaving slippers reminded him of the Bernie mittens that have been popping up all over the internet.

How about springtime flowers? It’s not spring yet, but the daffodils are here.

So are the almond flowers.

I don’t usually have the patience to scour the wool in locks even though it would save a lot of time at the other end of processing. I pulled out some locks that had more VM (vegetable matter) than I would like. I’m going to see how clean I can get them with flicking after washing. That will go much faster if they are already organized.

How about some goats? These are mothers with last year’s daughters. That’s Ellie and her daughter on the left and Amelia with hers on the right. Amelia is pregnant again.

One last random photo. The redbud is going to bloom soon. Hope springs eternal! And we’re getting our Covid vaccines Monday—have to drive an hour for it but I finally tracked it down.

Maybe you have never heard of a Temperature Blanket. If you knit or crochet then it’s more likely that you have. They seem to be the rage or maybe it’s just that I have become obsessed now so I’ve spent a lot of time thinking about it. The idea is that you record the daily temperature using color in a knitted or crocheted piece. Coming at it from another direction, the temps provide a pattern with which to create a unique or personalized piece. Often people use this as an interesting way to create their project over the period of a year.

I don’t know if this is the origin of the idea but there is a Tempestry Project website. They state: “One of the ongoing problems inherent in discussions about climate change is the vast scale of the conversation. The Tempestry Project’s goal is to scale this down into something that is accurate, tangible, relatable, and beautiful. Tempestry Project blends fiber art with temperature data to create a bridge between global climate and our own personal experiences through knitted or crocheted temperature tapestries, or “Tempestries.” Each Tempestry represents the daily high temperature for a given year and location, January at the bottom and December at the top (think bar graphs!)”

My interest in this began when a customer came to buy yarn for her own blanket. I had just started carrying the new Ashford DK yarn and she thought that would be just right. It comes in great colors and is very affordable. Then I remembered that a friend had knitted a pair of Tempestry Banners to be donated to her favorite National Park for an exhibit about climate. My friend, Lisa, provided these photos:

These banners are knitted using colors that represent the high temperatures for each day of 1916 and 2016. Beads along the right side indicate precipitation.

But wait! I’m a weaver. I want to weave a temperature blanket. There are a lot of factors to consider and it starts to get complicated. Here are some of the things I have thought about with ideas explained below.

It’s one thing to knit or crochet a row each day for a year and keep the project in a bag. To weave a row each day that means that the loom is tied up on that one project for a whole year.

Color range. Assign a color for every 5 degrees? Every 10 degrees?

So far everything I’ve seen uses high temperatures. What about the lows? Aren’t they important too, not only for the discussion of climate change, but even if the intent is to lend an overall feel of how we experienced the year.

Use temperatures for where you live? If you travel, use temperatures of where you happened to be each day? Or use temperatures of the year of someone’s birth or marriage or?

What yarn?

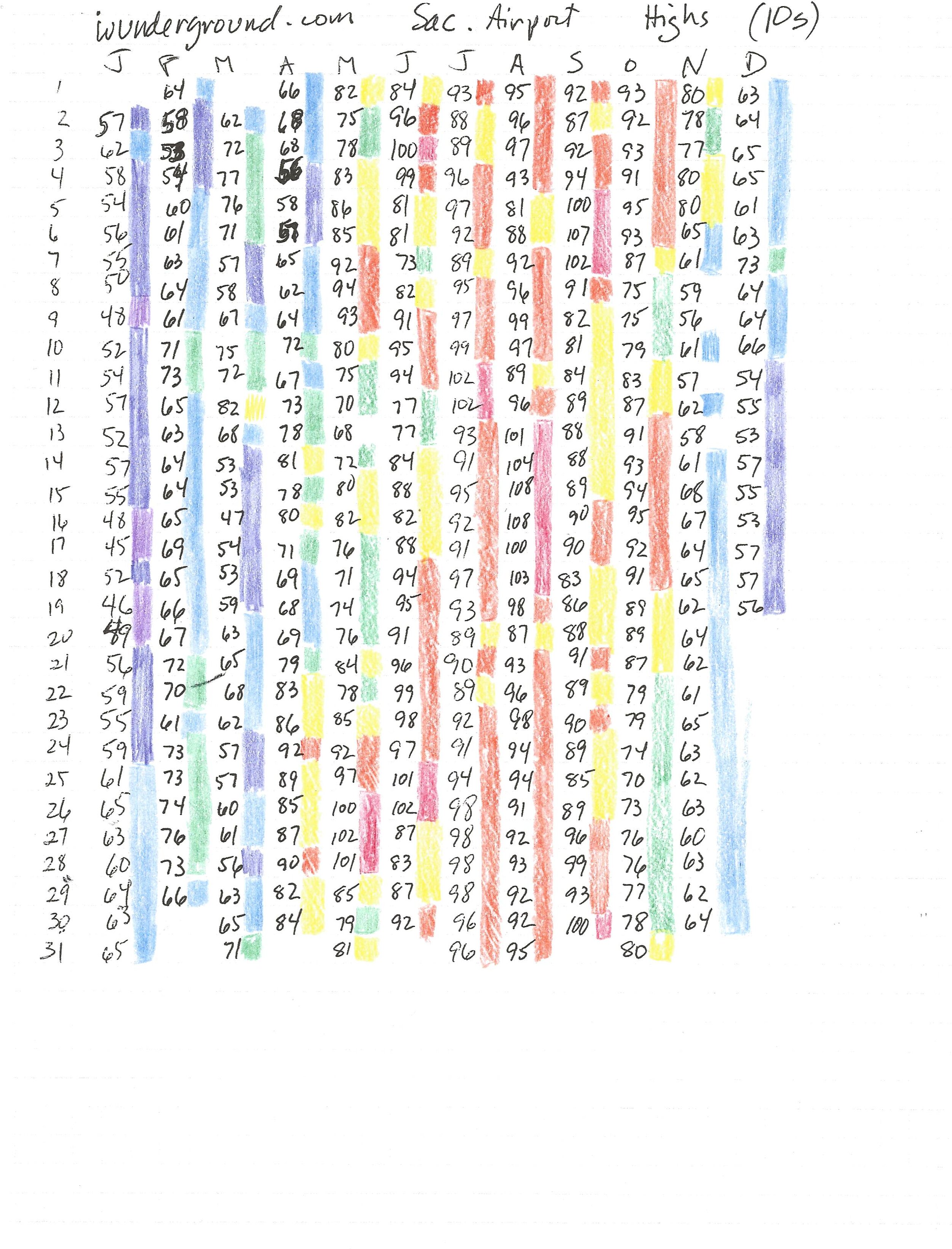

I’ll give you the answers to some of these later. But first let me explain my thought process. I knew it wasn’t practical to tie up a loom for a whole year but I could do a project that covered a whole year. So for the first blanket I’d weave 2020 temperatures. I explored sources of temperature data made a chart.

I was already December 20 so I’ll have to look up numbers if I want to complete the chart for 2020. I made a similar chart for the lows. A knitted blanket starts at one edge (January 1 temperature) and works forward for 365 rows. With weaving I could use two sets of numbers because I am working with warp and weft. What if the warp was one set of numbers (low temps) and the weft was the highs? There are some issues with number of threads as it relates to the scale of the project and the size of the loom, but I’m still working on that. I wanted to move on to color.

I got out my colored pencils and assigned colors to temperature ranges of 5 degrees. That is 15 colors! Is that realistic? Maybe not for a couple of reasons. But I forged ahead. I photocopied the charts of highs and lows so that I could try out the colors.

This is not how the blanket would look because these months are shown with the days in columns. A woven project would be made with each of those days indicating one thread, either in warp or weft.

This is the chart with the lows for each day. Quite different! Next I thought about yarn. I had already decided that the new Ashford DK yarn would be perfect for this. I know that part of my business is in promoting our own locally grown fiber, and I do love the wool yarn that I am having spun by three U.S. mills (2 in California). But I don’t feel bad promoting this yarn—it is “locally produced” in New Zealand from sustainable New Zealand sheep farms and I think Ashford is a reputable company to support…and the yarn is very affordable and easy to use with a lot of color choices. It compliments my own Timm Ranch yarn very well. Here is the link to this yarn.

This is 12 of the colors that I chose for my initial sampling. I wanted three additional colors but they are backordered and will be here in a few weeks.

I wound a warp for some samples. I didn’t use a particular color order or specific number of threads. I wanted to see how the cloth would look if some of the stripes were as few as 2 threads (one day because it’s easier to wind warp in pairs) and some up to an inch. I used the same color order in the weft for two of the samples and I used two different weave structures.

Here is how the sample looks when woven in broken twill.

This weave structure alternates plain weave and twill picks and looks different on each side.

These samples are based on the assumption that there will be color changes in warp and weft. What about setting up an easier project where one direction uses a solid color?

This is the same warp woven in broken twill with black or white.

This sample uses that plain weave/twill pattern but with the solid black weft.

So there is a lot to think about in planning this woven project.

Color changes in warp and weft. Too much going on? Will be more interesting if the lows are one direction and the highs are the other. A fun project to plan and weave.

Color changes in warp with solid weft. All the planning and paying attention is for the warp. Easy to weave.

Solid warp with color changes in weft. Easy to wind warp. Not as easy to weave with color changes. Stopping and starting yarn. Fulling these samples prevented loose ends from being a problem.

Use fewer colors? I tried the same chart using 10 degree increments for color changes. That requires only 8 colors.

The highs in 10 degree color change increments.

The chart of lows in 10 degree color increments is above.

One reason for writing this blog post is to get all my thoughts in one place. Another is to generate some interest in this project (and maybe sell some yarn to be honest). Who wants to work on a color blanket or scarf or wall hanging? You don’t have to weave it. I’ll happily show my yarn to knitters and crocheters too. Here is one more idea for those who might want to do a little each day.

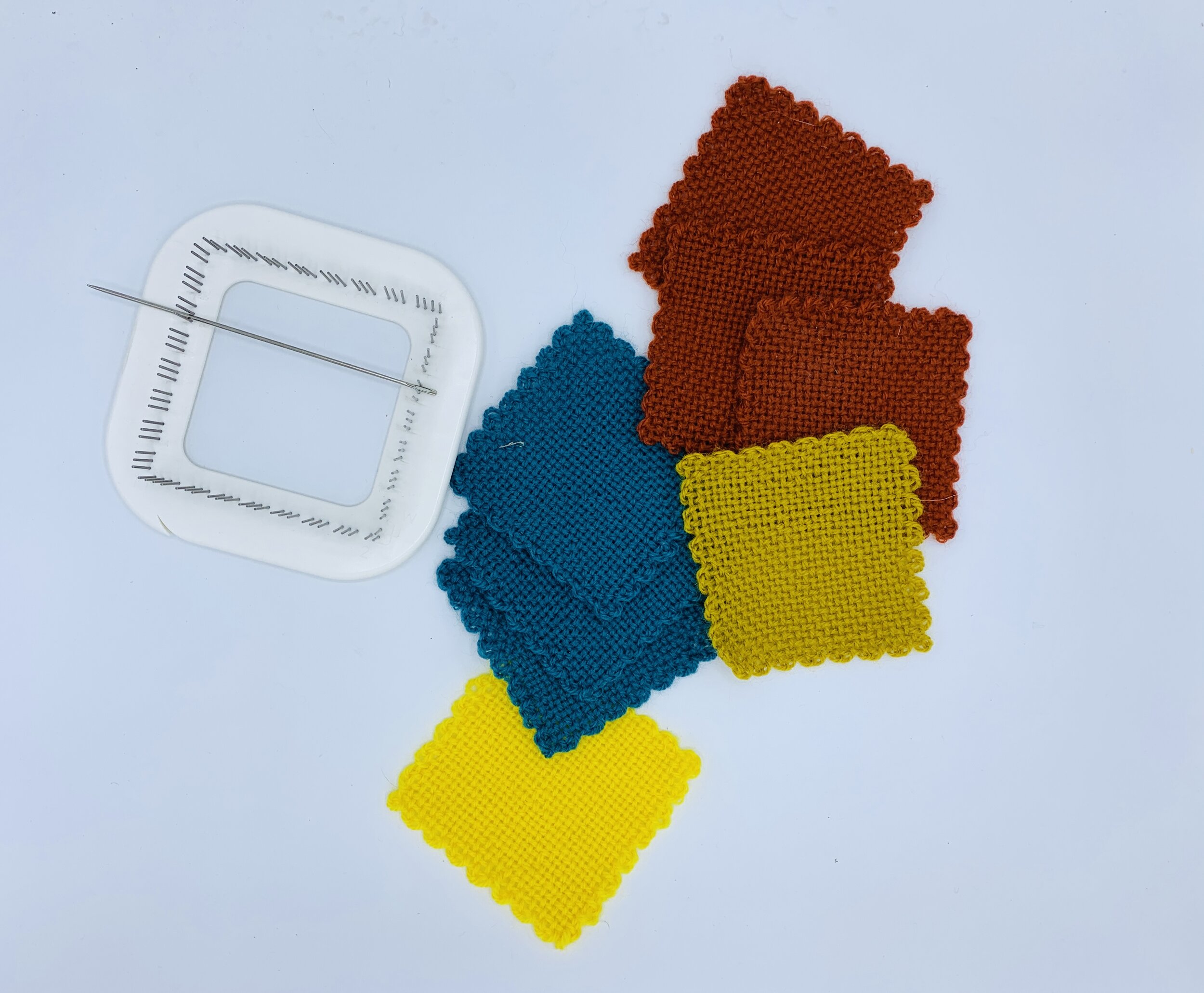

This yarn works great with the Schacht Zoom Loom and you can weave a square in 15 minutes. I am going to weave all the 2020 colors and put the blanket together as an example. Hmmm. 365 days x 15 minutes = 91.25 hours. Don’t hold your breath waiting for me to finish this one.

Look for future posts about the progress of this idea.

I wrote about my experience at this year’s Lambtown in Dixon, California here.

On Sunday morning while I was getting my vendor booth ready for the day the Sheep to Shawl (S2S) teams were gathering. There were to be seven under this tent and one of them was the Farm Club team! Before Lambtown opened for business I looked for the other Farm Club members who were supporting Lambtown one way or another. We had pretty good representation!

Gynna and Roy (along with Hank this year) were the brains behind Lambtown the last few years and responsible for it’s revival and success.

Jackie helped in the Fibershed Coop booth but was also staffing the booth for Solano County CART (Community Animal Response Team). Stephany spent most of her time helping to organize and then staff the Fibershed booth.

Shoppers are an important part of the event. Dona and Mary exemplify the best kind of shopper.

Lisa volunteered at Lambtown and did her share of shopping as well, finding the naturally colored cotton that I was selling.

As I got back to the Sheep-to-Shawl tent I found five more Farm Club members. Alison and Marina were already committed to the Silverado Spinster’s team, but it was Alison that got the Farm Club team organized back in July.

Here Kathleen has joined them, also on the Silverado team.

The all-important tea for Alison.

I didn’t get a photo of Carol but she is represented on this team.

Farm Club member, Deborah, was also on a different team—Spindles and Flyers.

This is the Meridian Jacobs’ Farm Club team (and me) just before the competition started. There are 4 spinners, 1 plyer, 1 “go-fer”, 1 educator, and the weaver. They can all work on fiber prep but they all have to stick to their other jobs. The loom was warped with handspun Jacob wool of course.

Here are the posters that the team prepared as part of the education component of the contest.

When the call to start was made, the team all began fiber prep.

Opening locks before putting them through the drum carder.

Note the bandaid box. Safety first!

Seen on a spinning wheel.

Spinning is underway.

Brenda seemed to be having a good time.

The weaver, Reba, had to focus since she had a rather long treadling sequence to get the pattern she planned.

I love that our team thought up the “secret message” that unrolls as the warp is woven.

Alison, on the neighboring team, used headphones to help her concentration while weaving.

This is the beautiful pattern that Reba wove. The shawl was not finished in the allotted time, and the team agreed that it was better to leave it on the loom and finish it later rather than cut if off just to make a time limit.

I can’t wait to see this when it is really finished! Go Team!

A post full of random photos from a week of weaving, sheep care, teaching, and family stuff.

Read MoreWeaving blankets from dozens of natural colored locally produced wool yarns.

Read MoreAt Meridian Jacobs farm we raise Jacob sheep and sell locally grown wool fiber, yarn, and handwoven goods. We teach fiber classes and sell Ashford, Clemes & Clemes, and Schacht spinning and weaving equipment. We encourage farm visits with field trips and our unique Farm Club.

Search blog posts since 2019. If the search says it can’t find a post try putting in your search word a second time. I don’t know why but the second time it seems to work.

Search the entire website, including older blog posts.