Road Trip - Day 8 - Pendleton

/It's been several days since I wrote the post about Day 7 of our vacation. The vacation wasn't quite over. We needed to be back home on Tuesday but there were two places to visit in Oregon. (Actually I had marked many others on the map in my head--Hell's Canyon National Recreation Area, John Day Fossil Beds National Monument, a friend in Boise, a cousin near Portland--but those will all have to wait for another trip.)

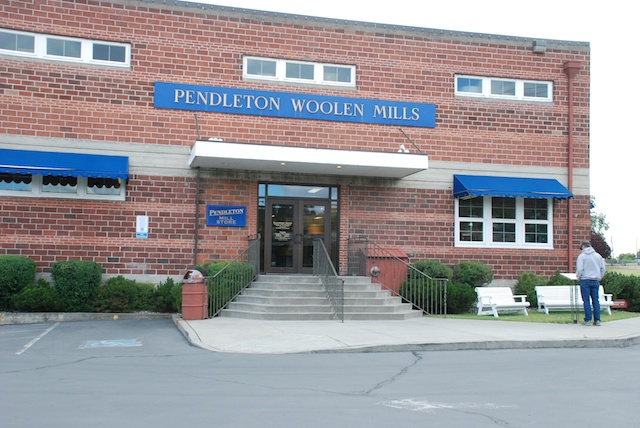

We arrived in Pendleton...  ...and easily found the woolen mill. There is also a mill near Portland. That is where they weave cloth for the Pendleton clothing line. At this mill in Pendleton they spin and weave blankets.

...and easily found the woolen mill. There is also a mill near Portland. That is where they weave cloth for the Pendleton clothing line. At this mill in Pendleton they spin and weave blankets.  There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back!

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass. Pencil roving is spun onto big spools and the yarn is later transferred to cones.

Pencil roving is spun onto big spools and the yarn is later transferred to cones.

The yarn is steamed to set the twist. Now I can't remember the details. I think it was steamed for an hour or so.

The yarn is steamed to set the twist. Now I can't remember the details. I think it was steamed for an hour or so. This is a view from the second floor looking down on the looms that are on the first floor.

This is a view from the second floor looking down on the looms that are on the first floor. Above the looms are the computers that operate them and fans that keep the lint from settling and, thereby, prevent overheating.

Above the looms are the computers that operate them and fans that keep the lint from settling and, thereby, prevent overheating. Here is where I now have more questions than answers. This is one of the Jacquard looms. A Jacquard loom can weave complicated patterns because all the threads operate independently. Notice the selvedge threads that are wound separately.

Here is where I now have more questions than answers. This is one of the Jacquard looms. A Jacquard loom can weave complicated patterns because all the threads operate independently. Notice the selvedge threads that are wound separately. It is only after looking at this photo that I see the selvedges being cut off as the cloth rolls onto the cloth beam. At least I think that is what I am seeing. (This will only have significance to those of you who are weavers.)

It is only after looking at this photo that I see the selvedges being cut off as the cloth rolls onto the cloth beam. At least I think that is what I am seeing. (This will only have significance to those of you who are weavers.) This is one of the dobby looms. I think that guide said that with their newer dobby looms a blanket takes 15 minutes to weave.

This is one of the dobby looms. I think that guide said that with their newer dobby looms a blanket takes 15 minutes to weave. The blankets in a continuous roll are inspected for flaws as they roll over a light table (middle of the photo where the bright light is).

The blankets in a continuous roll are inspected for flaws as they roll over a light table (middle of the photo where the bright light is).  Blankets ready for finishing touches.

Blankets ready for finishing touches. Bags of selvedges ready to sell to people who want to make rugs.

Bags of selvedges ready to sell to people who want to make rugs. We left with a few bags of our own. Dan wanted to point out that his purchase (BBQ sauce) fit into that little paper bag.

We left with a few bags of our own. Dan wanted to point out that his purchase (BBQ sauce) fit into that little paper bag.

Next post: Second half of Day 8--sheep.