Sustainable Cotton Tour

Earlier this week Dona and I went on a Cotton Farm Tour organized through the Sustainable Cotton Project (SCP) and sponsored by The North Face and the CA Sate Water Resources Control Board. The website of the SCP says: "Since 1996, the SCP has been dedicated to the production and promotion of sustainably grown domestic cotton fiber. In the field we work with innovative growers to produce a high-quality fiber without using the most toxic pesticides and herbicides. And, in the industry we connect growers, manufacturers and consumers to develop a Cleaner Cotton supply chain."  The tour was a very full day and I took dozens of photos. I've tried to narrow them down for this post but there are still a lot.

The tour was a very full day and I took dozens of photos. I've tried to narrow them down for this post but there are still a lot. In most cotton crops a defoliant is applied prior to harvest.

In most cotton crops a defoliant is applied prior to harvest.  I was reading up on this and find that, as in most things, it is a whole lot more complicated than that simple statement implies. Dozens of factors are involved in the decision of to defoliate or not, type of defoliant (hormonal or herbicidal), and timing of defoliation (based on crop maturity and desired harvest time with some weather predicting skill necessary).

I was reading up on this and find that, as in most things, it is a whole lot more complicated than that simple statement implies. Dozens of factors are involved in the decision of to defoliate or not, type of defoliant (hormonal or herbicidal), and timing of defoliation (based on crop maturity and desired harvest time with some weather predicting skill necessary). Most cotton in the U.S. is harvested by machines that pick four or more rows at a time.

Most cotton in the U.S. is harvested by machines that pick four or more rows at a time.

Close-up of the rotating barb spindles that pluck the cotton from the plant.

Close-up of the rotating barb spindles that pluck the cotton from the plant.  Warning signs on the harvester.

Warning signs on the harvester. The fiber is sucked up into the back of the harvester.

The fiber is sucked up into the back of the harvester. Dona took this photo of me on the harvester and the one below of me watching the module packing.

Dona took this photo of me on the harvester and the one below of me watching the module packing. When the harvester is full the load of cotton is dumped into the module builder...

When the harvester is full the load of cotton is dumped into the module builder... ...where it is hydraulically pressed into modules that will produce up to 14 bales of cotton.

...where it is hydraulically pressed into modules that will produce up to 14 bales of cotton. This is cotton in the module builder.

This is cotton in the module builder. Modules covered with plastic and waiting to go to the gin.

Modules covered with plastic and waiting to go to the gin. You can see the already-harvested rows.

You can see the already-harvested rows.

After watching the harvest for awhile we went to the nearby gin where the manager spoke to us before we toured the gin. He showed us examples of ginned cotton and by-products. Acala cotton (left) is a brighter white than Pima and it's seeds remain fibrous. Cotton seed (60% of the weight of the harvest) is an important by-product of cotton production. Most is sold as a protein supplement for dairy cattle. (I found it interesting that the "cleaner" Pima seed doesn't stay in the cow's rumen long enough to be digested and needs addition of fiber to keep it there.)

He showed us examples of ginned cotton and by-products. Acala cotton (left) is a brighter white than Pima and it's seeds remain fibrous. Cotton seed (60% of the weight of the harvest) is an important by-product of cotton production. Most is sold as a protein supplement for dairy cattle. (I found it interesting that the "cleaner" Pima seed doesn't stay in the cow's rumen long enough to be digested and needs addition of fiber to keep it there.)  Piles of cotton seed.

Piles of cotton seed. A module just before it enters the gin.

A module just before it enters the gin. Covers removed from the modules.

Covers removed from the modules. We waited at this entrance to the gin as small groups were taken through. Finally, because we were on a schedule and lunch was waiting, we were all allowed to walk through the gin.

We waited at this entrance to the gin as small groups were taken through. Finally, because we were on a schedule and lunch was waiting, we were all allowed to walk through the gin.  The process was described to us prior to entering the gin but once inside I wasn't sure which machine was which. There are dozens of machines and tubes are running everywhere.

The process was described to us prior to entering the gin but once inside I wasn't sure which machine was which. There are dozens of machines and tubes are running everywhere.  In the ginning process modules are broken apart and the cotton enters a dryer which removes excess moisture. It passes through several rotating, spiked cylinder cleaners that break up large clumps and remove soil and leaves. The saw gin separates the fibers from the seeds and lint cleaners separate immature seeds and any remaining foreign matter.

In the ginning process modules are broken apart and the cotton enters a dryer which removes excess moisture. It passes through several rotating, spiked cylinder cleaners that break up large clumps and remove soil and leaves. The saw gin separates the fibers from the seeds and lint cleaners separate immature seeds and any remaining foreign matter.  The cotton then enters a press where it is formed into 500 pound bales.

The cotton then enters a press where it is formed into 500 pound bales. These are the wires that hold the bales together.

These are the wires that hold the bales together. The bales are wrapped with plastic. (Some were in cotton bags for a specific destination.)

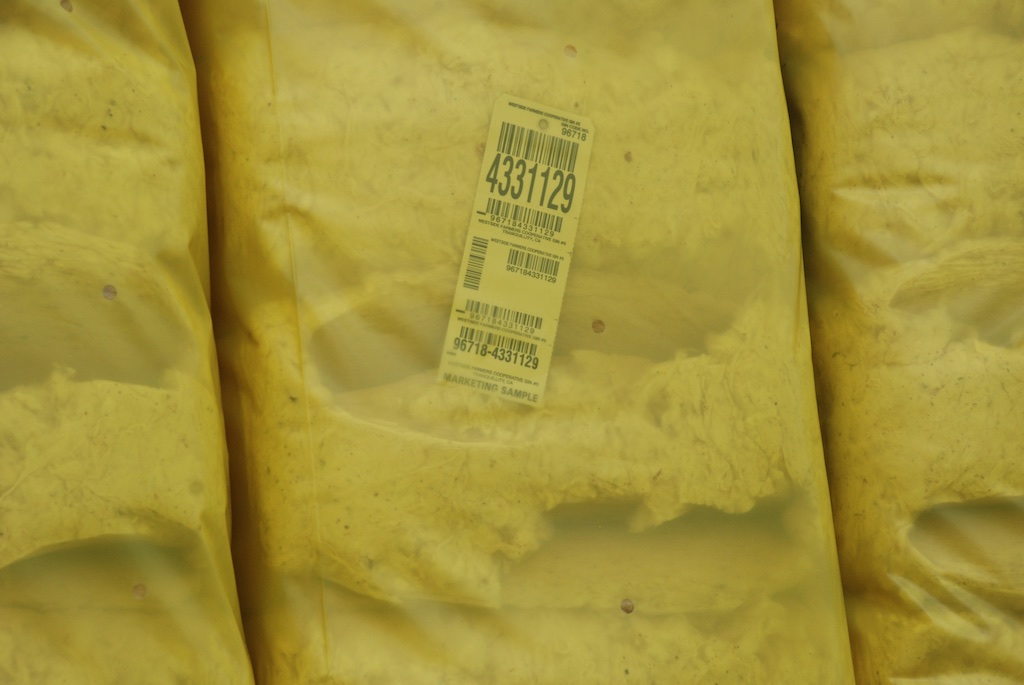

The bales are wrapped with plastic. (Some were in cotton bags for a specific destination.) Each bale is labeled so that it can be traced back to the field in which is was grown...

Each bale is labeled so that it can be traced back to the field in which is was grown... ...and then loaded for transport.

...and then loaded for transport. Even the gin trash has a value, being used for cattle bedding.

Even the gin trash has a value, being used for cattle bedding.

This brought us up to lunchtime. I'll finish the story in another post.