Road Trip to SD - Day 3 - Wool Mill

We camped at the Lost Cabin campground in the Bighorn Mountains. We needn't have been concerned about being crowded out by hoards of motorcycle riders. There were only one or two other campers. It was hard, living and working outside in the Central Valley, to imagine needing wool gloves, hats, etc. I'm glad that I had brought those and that before we left I had grabbed my heavy chore coat off the hook where it had been since the spring. The night was cold camping at 9400 feet elevation. (I know, that's all relative, and some of you laugh at what I think is cold. But nevertheless I was cold.) It was almost dusk by the time we finished eating and cleaned up dishes and I was ready to get in a sleeping bag. I was warm enough, but spent a lot of time reading in the middle of the night when I couldn't sleep.

We meant to get an early start, but it was already well into the morning when I woke up. Hey, it's vacation time! And there is a time zone difference too. Dan made his coffee and we got on the road to Buffalo.

This was our destination.

Mountain Meadow Wool is the company that spun this year's yarn and I was excited to meet the people there and see the mill.

Here is the entrance.

It opens into a showroom and sales area.

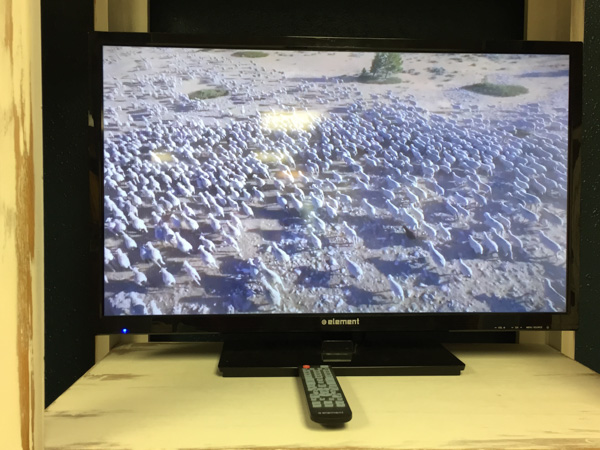

There are well-made videos showing of local sheep ranches where the wool is sourced and the mill in production.

Ben took us into the mill. He showed us this wall where bales and bags are piled waiting to be processed. This wool will be used for Mountain Meadow's own line of yarn. It was interesting that the wool stacked here is this year's production for the Mountain Meadow lines of yarn whereas for the "big" companies that might amount to only one days' production.

The scouring line starts here.

First, is the skirting table, very similar to mine with the PVC cross-pieces. One person checks all the wool as it comes through. He will pull out fiber that looks too short, too full of VM, or contaminated with paint marking.

This was nice fiber, but Ben said that the paint wouldn't wash out so it is discarded. The fiber pulled out here goes into the baler that is behind the skirting table (photo above this one). I don't remember where Ben said that this goes, but there is a market for it when they get a large amount.

The wool goes up this belt...

...and through the bale opener before it goes through the scouring line, which Ben and his team have spent years developing to work for a mill of this size.

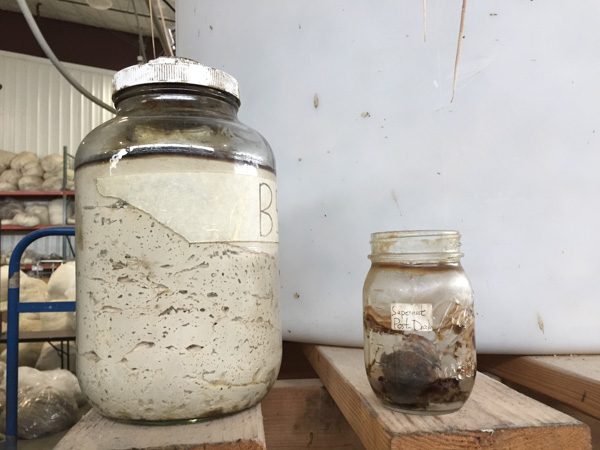

Nearby there were several large plastic barrels (30-50 gallons?) connected by pipes and tubing that is Ben's work-in-progress to biologically manage the solids that become waste products of the scouring process. This includes lanolin and a lot of dirt. He is still working to perfect the system that includes lanolin-consuming bacteria (if I remember correctly). This jar is full of some of the waste products.

The carder is right in the middle of this room but I didn't get any photos of it. After carding the wool goes through the pin drafter--5 times!

This comb in the pin drafter helps remove short pieces and debris to create a smoother product.

Spinning is next.

It takes about 6 hours to spin up the fiber in each box unless they are spinning very fine yarn. Then it can take 2-1/2 days! No wonder it costs more to have fine yarn spun.

Combing is an additional process...

...which creates a product called "top", that has no short pieces or cross fibers in it.

There can be a lot of waste after combing but Mountain Meadow Wool uses that waste to create dryer balls. My dryer balls are here.

Yarn is then wound on cones and/or skeined.

Mountain Meadow Wool also has a dye kitchen for the yarn that they market.

Ben took us into a room with finished goods, experimental products, R&D. Mountain Meadow Wool offers some pieces for sale and also the option to have some items made with a producers own wool. I admired the blankets being woven.

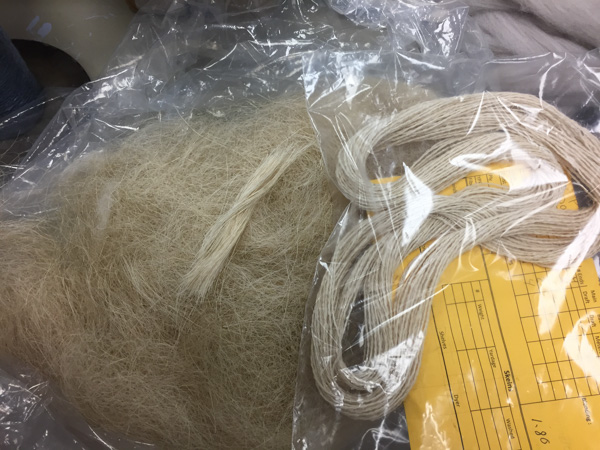

People have sent fibers to see how the mill can handle them. The fiber above is a coarse plant fiber. I can't remember what it is--something like agave, or at least it reminded me of that plant family.

This one I remember. Someone sent Ben bear fiber to spin.

I appreciate Ben taking time out of his day, and at the end of a week when they have been short-handed, to show us around. It helped me to discuss with him fiber prep and fiber quality. Quality control of the yarn begins at the producer's skirting table. I love the yarn they are producing at this mill and it's nice to know the family.

Where to next? It was about 1:00. We at lunch at a local sandwich place and looked at our maps. It wasn't far to Devil's Tower National Monument--only about two pages away in the map book. Onward!